Industrial filter elements are mainly used in mechanical equipment and are divided into the following four categories:

1. Hydraulic system filtration

The pollution control of the hydraulic filtration system is a technology for the formation, elimination and control of particulate pollutants in the hydraulic system. The interior of the stainless steel fired filter element is processed into a folded wave shape (used to expand the filtration area). Stainless steel filter elements are suitable for liquid and solid separation technology in almost all industrial fields.

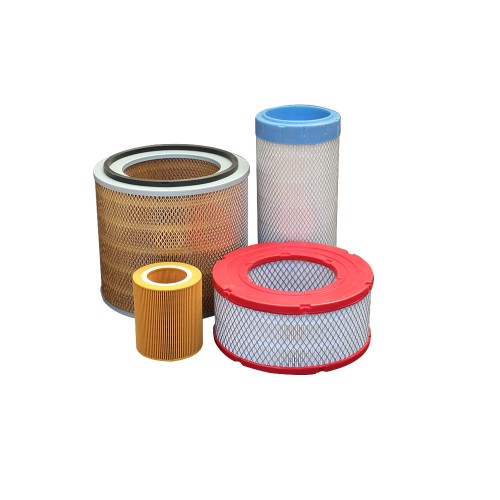

2. Lubrication system filtration

The lubrication system is mainly to purify the oil in the lubrication system of the internal combustion engine to prevent the cylinder from being strained and worn. The oil filter element in the internal combustion engine is also supplied as a tank type like a diesel filter element.

3. Air filtration

Air filtration systems are installed on internal combustion engines, air compressors, jet engines and other aerodynamic equipment. In a broad sense, air filtration also refers to the filtration of pollutants discharged from large factories and the filtration of clean rooms.

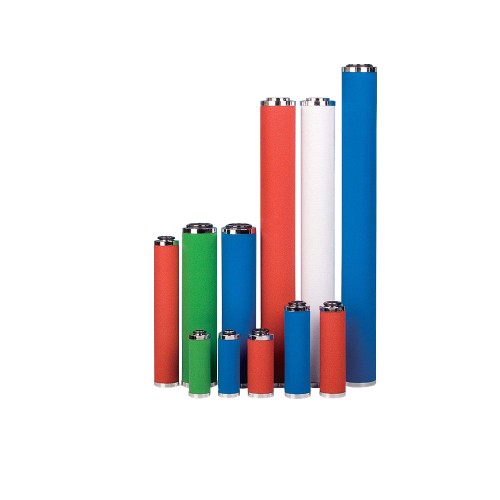

4. Water Filtration

Water filters are used in petroleum, chemical, energy, food, medicine and other industrial fields. The main water treatment equipment includes: softened water device, pure water device, high-purity water device, waste water recovery device, constant pressure water supply device, bag water filter, Quartz sand filter, etc. Some products are used in PetroChina, Sinopec and other enterprises.

Post time: May-15-2023