When it comes to filter elements, everyone will ask what is filtration and why is it necessary to filter? Filtration refers to an operation in which a certain device is used to strip off solid particle impurities in gas or liquid. Its function is to maintain the cleanliness of the filter items and effectively control pollutants, thereby ensuring the normal use of industrial machinery.

Industrial filter elements can be divided into the following three categories according to the structure of the filter element:

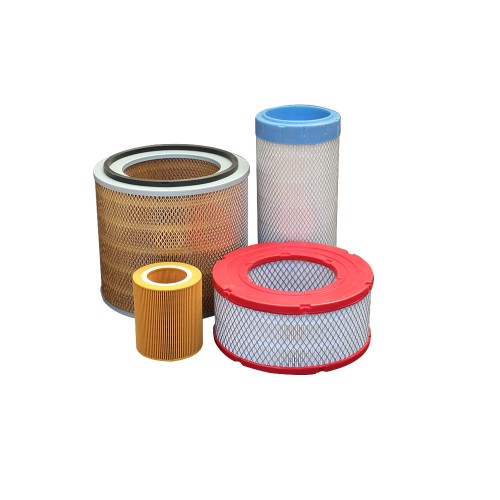

1 Surface type

All the impurities in the filtration are blocked on the surface of the filter element, and the solid particles larger than the standard range are filtered out by using a special filter element material. Specifically, it can be divided into line gap type, mesh type and sheet type.

2 Depth type

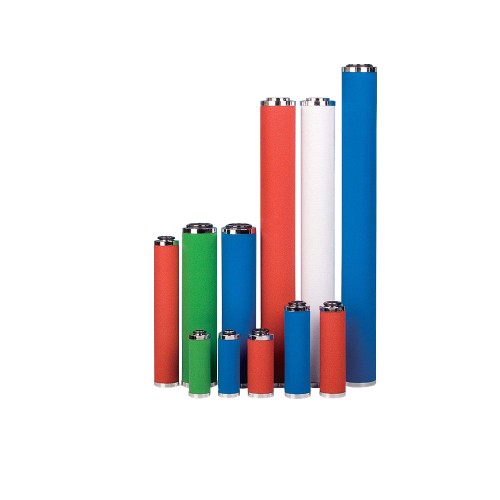

Utilizing the feature of the deep thickness of the filter element material, solid pollutants are filtered out when passing through the long channel inside the filter layer, which has the advantage of high filtration accuracy.

However, the particle size of the impurities to be filtered cannot be strictly limited, and the volume of the filter material is relatively large, and the pressure loss is also relatively large. The material of the depth type filter element can be felt, rayon, stainless steel fiber, powder sintering, etc.

3 Adsorption type

Rely on the magnetic field force of the magnetic filter material to attract iron filings and magnetic abrasives. The filter element is made of a magnet, which can absorb iron filings, iron powder or magnetic grinding powder in the oil. It is often made into a composite filter together with other filter elements, and the scope of application will be limited.

Post time: May-13-2023