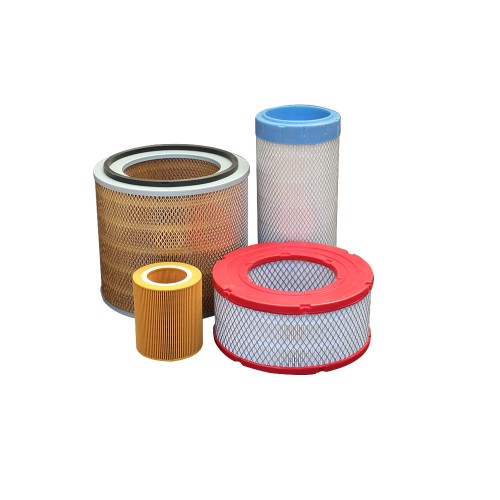

When the air compressor oil and gas separator works for a period of time and more dust is adsorbed on the filter element, the gas resistance passing through the air compressor oil and gas separator increases. When the circulating gas resistance is higher than 6.3KPa, the air filter clogging sensor installed between the air filter and the turbocharger will transmit the signal to the air filter clogging indicator light on the instrument panel. When the indicator light turns on The air filter should be serviced at the same time.

Air compressor oil and gas separator failure causes and troubleshooting methods:

1. The engine is weak and the cap is black smoke.

Cause: filter element clogged. Remedy: blow clean the filter element or replace the filter element.

Reason: air filter sucks paper scraps or rags, etc. Remedy: clean up.

Cause: rainwater enters the air filter. Remedy: dry the filter element or replace it.

2. The engine is worn early.

Reason: Intake short circuit. Remedy: Check error proofing.

Reason: filter element is damaged and failed. Remedy: replace.

Cause: dust bag failed. Remedy: replace.

Post time: Nov-07-2022