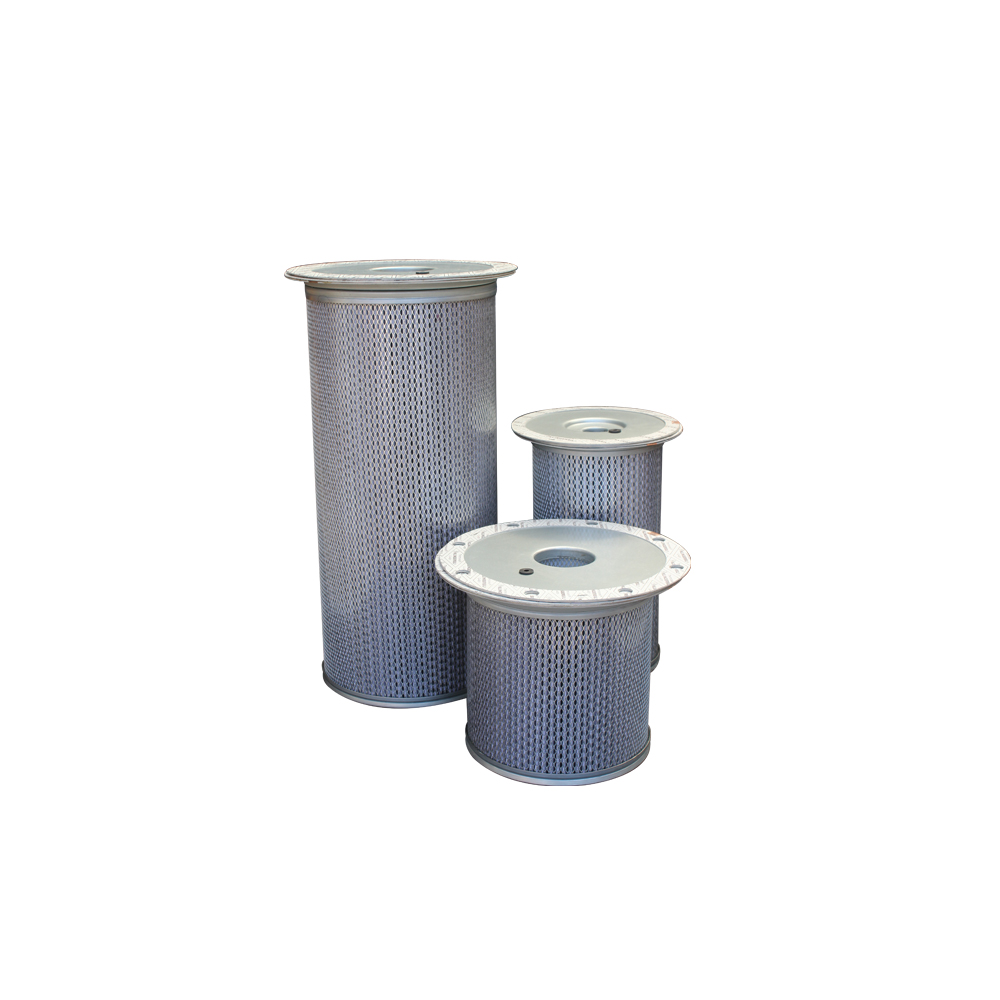

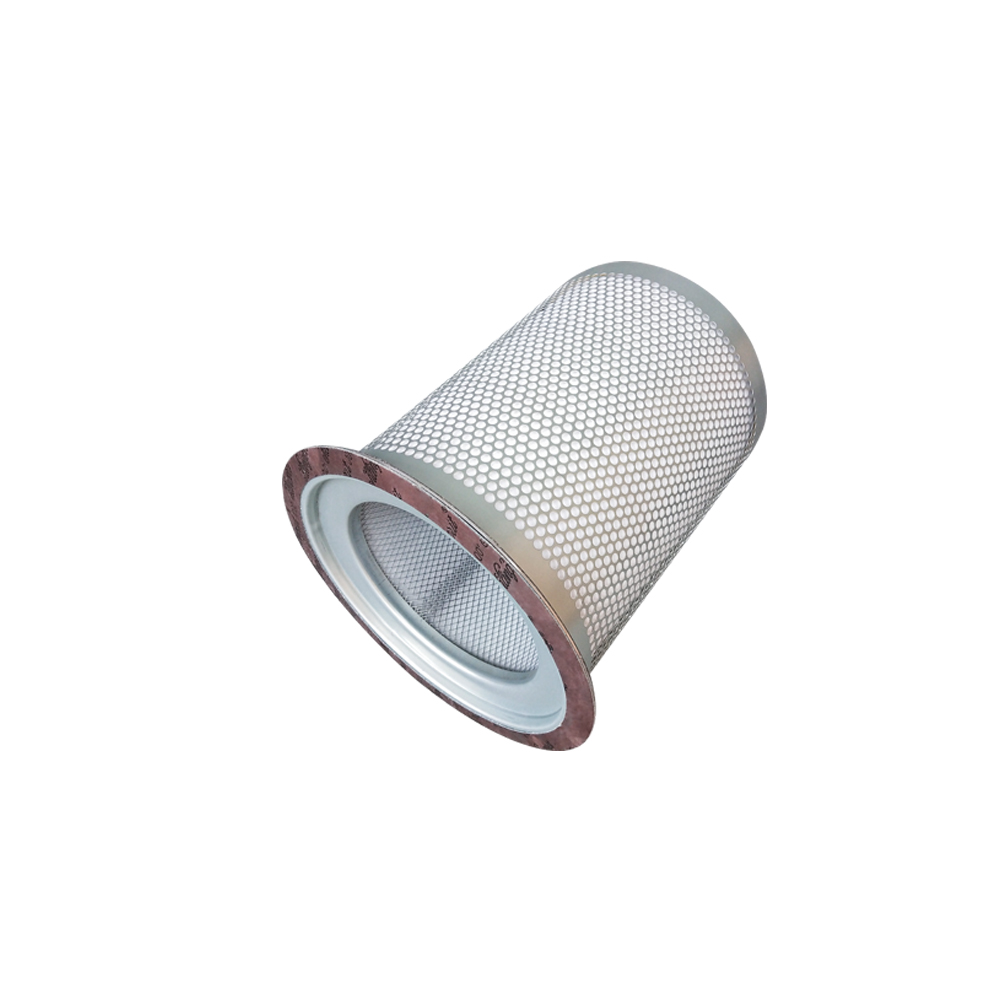

Rapid Delivery for disk sintered filter - Oil And Gas Separation Filter Elements For Air Compressors -odefilter

Rapid Delivery for disk sintered filter - Oil And Gas Separation Filter Elements For Air Compressors -odefilter Detail:

Introduction:

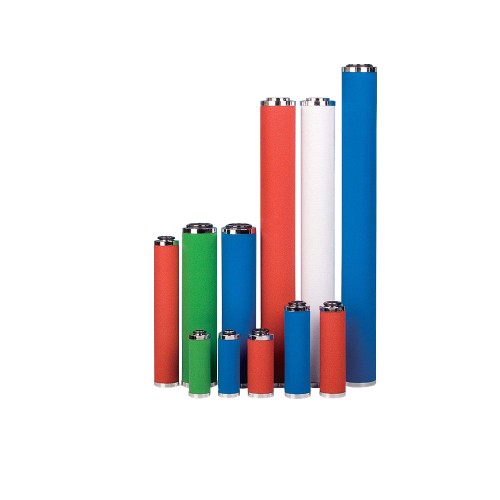

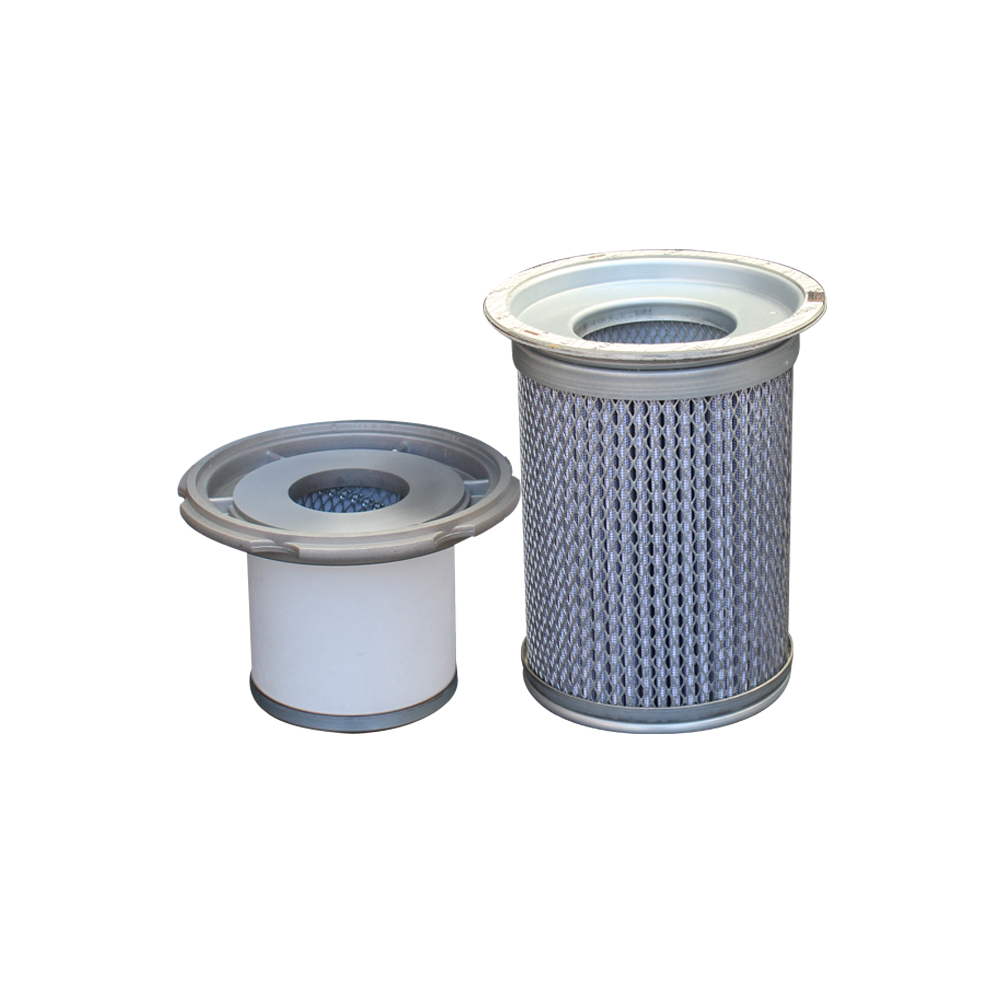

The working principle of the oil and gas separation filter element for the air compressor is ‘polymerization’. When the compressed air containing oil mist passes through the oil-air separator filter element, the micron-level glass fiber layer separates the oil droplets from the gas, then agglomerates into larger oil droplets and returns to the compressor oil circuit. This separation process can ensure that the oil consumption of the compressor and the amount of oil entering the compressed air pipe network are minimal. Ensure its normal operation.

Features:

Precise design

High efficiency and high performance

High sealing quality

Easy to replace and install

Specifications:

| Material: | glass fiber, filter paper etc. |

| Micron Rating: | ≤0.1μm |

| Efficiency: | 99% |

Applications:

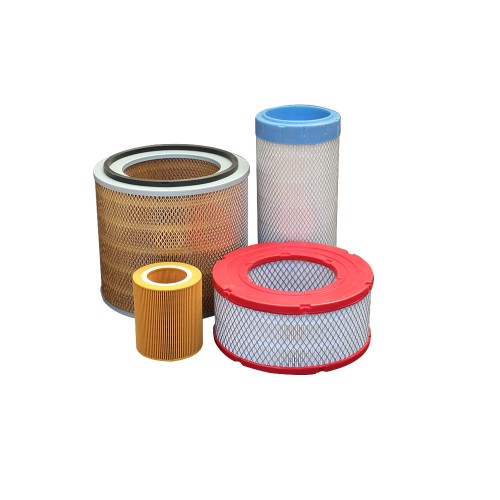

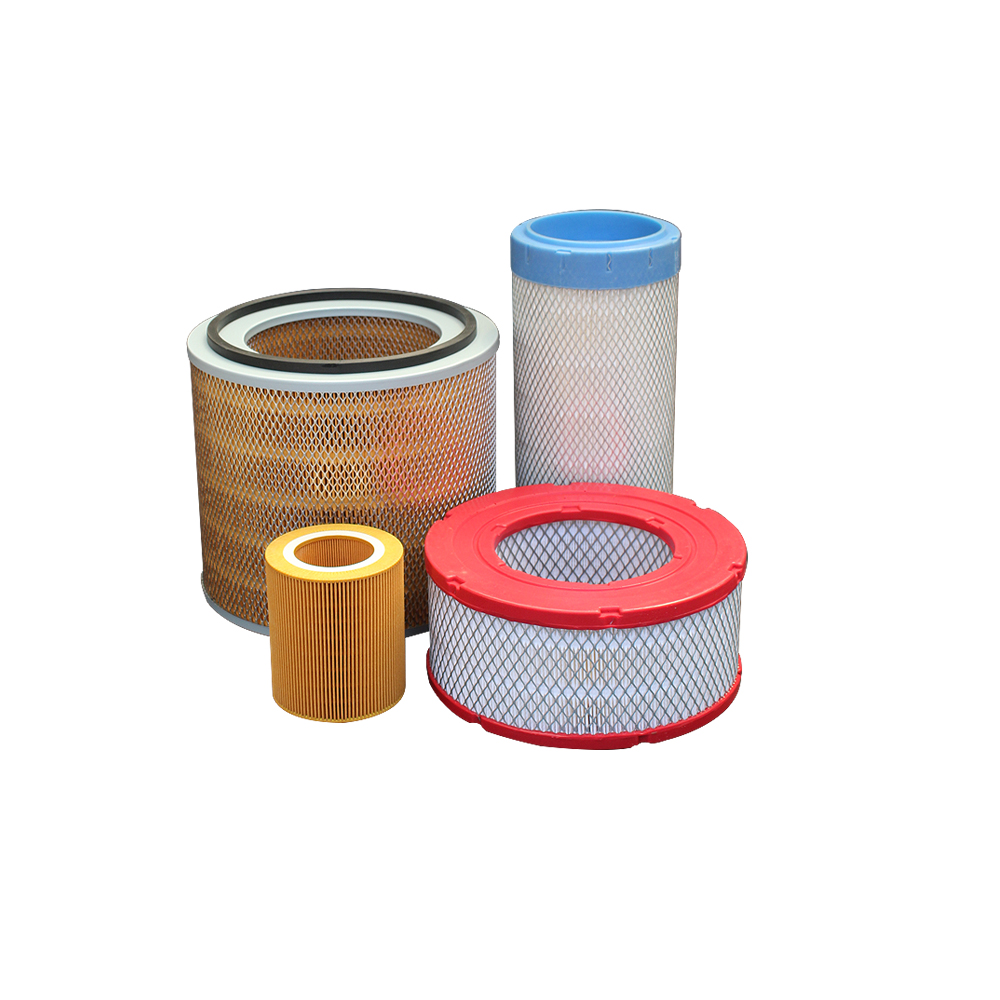

The oil and gas separation filter element for the air compressor is mainly used for oil mist separation in air compressor on air compressor equipment.

Product detail pictures:

Related Product Guide:

With reliable good quality system, great standing and perfect consumer support, the series of products and solutions produced by our organization are exported to quite a few countries and regions for Rapid Delivery for disk sintered filter - Oil And Gas Separation Filter Elements For Air Compressors -odefilter , The product will supply to all over the world, such as: Oman , Canada , Belarus , We seriously promise that we provide all the customers with the best quality products, the most competitive prices and the most prompt delivery. We hope to win a resplendent future for customers and ourselves.

The company can keep up with the changes in this industry market, product updates fast and the price is cheap, this is our second cooperation, it's good.